SERVICES

These are the SERVICES we offer at ELECTROSON INYECCIÓN, the company of the GRUPOELECTROSON that is a reference in the area of PLASTICS INJECTION.

Since the beginning, when we worked mainly in the automotive sector under the name of HEFI, we have enjoyed the recognition and satisfaction of our customers and the main agents in the channel. All this thanks to the quality of our products, services and our team.

All the phases of the production cycle, Manufacturing, Marketing, Logistics and Administration are carried out at the plant located in C/ de La Solana, 19.

While storage and distribution are located in the warehouse located in C/ Metano 11, both in Torrejón de Ardoz, Madrid.

We design, manufacture and develop with our own means the products we offer, we carry out a meticulous control of the processes and documentation.

All our work is carried out by qualified personnel of the organisation, who ensure compliance with customer specifications by means of continuous measuring instruments, providing maximum reliability and optimum price adjustments.

Both the Quality and Environmental Management System, as well as the Technology and the Human Factor that are part of ELECTROSON INYECCIÓN, are focused on the achievement of a final objective:

CUSTOMER SATISFACTION.

CONSULTING

We advise you throughout the whole process.

We improve efficiency and competitiveness.

We lower production costs.

We offer solutions adapted to the customer’s needs.

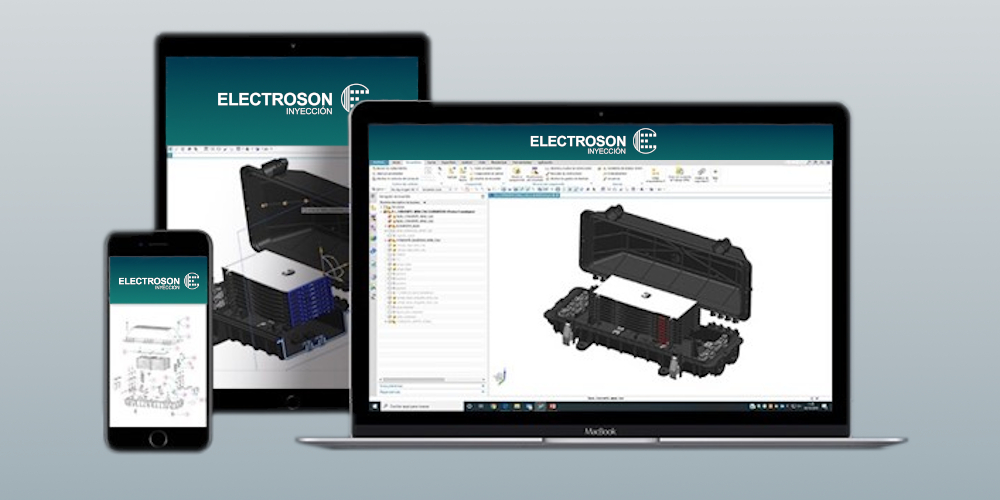

DESIGN

We create 3D designs to define the manufacture of a plastic injection moulding product.

The good design, intervenes in the quality of the product and seeks a lower assembly cost.

With a better design we optimise and achieve greater efficiency.

R&D

We have a specialised team that uses advanced technology.

We adjust costs for the manufacture of parts and moulds.

We use high technology in design and manufacture of computer-assisted prototypes.

RAPID PROTOTYPING

We design and 3D print prototypes in advance.

We evaluate the best materials and calculate the investment costs.

We measure the efficiency of the project before going into series production.

With the prototypes we adjust the final model, design and functional requirements.

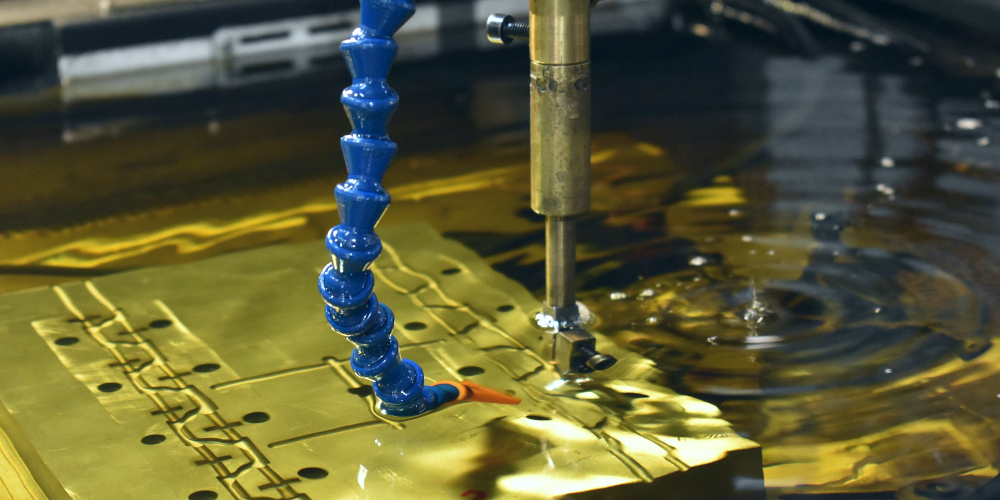

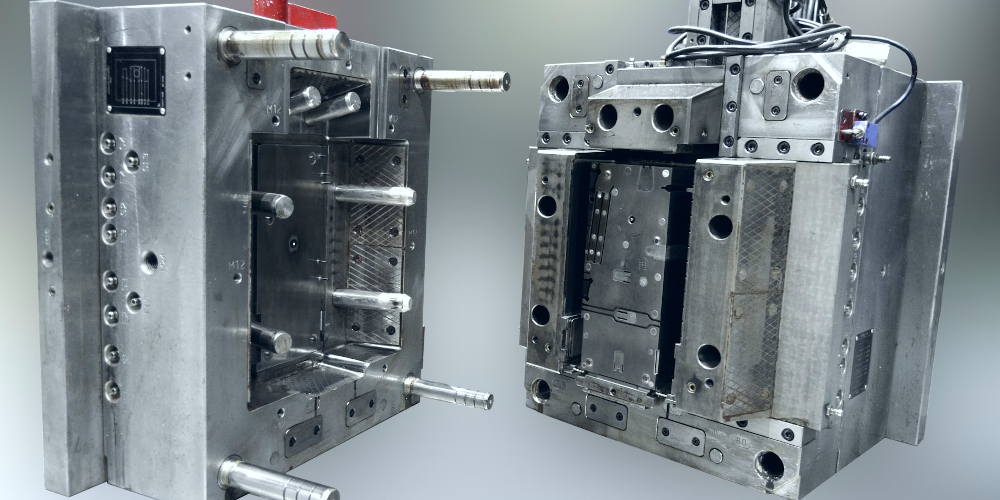

TOOLING

The useful life of the mould is determined by its design, material and operation.

They are high precision machines and require continuous maintenance.

We manufacture, maintain and repair the moulds for an efficient production

of the products we manufacture with them.

We constantly monitor the manufacturing process to ensure maximum quality.

TOOLING MAINTENANCE

We have our own in-house tooling department.

This allows us to be fast and precise in our work.

We create high precision parts, which is why intense care is required.

In addition to constant preventive and corrective maintenance of the moulds and tools.

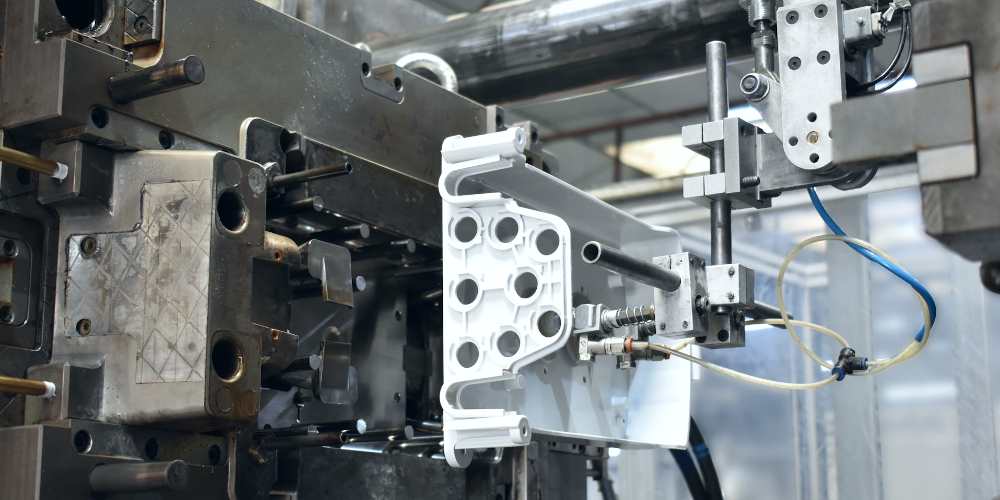

INJECTION MOULDING

At mould closing, the polymer is placed in the injection unit.

The polymer is injected into the mould at high temperatures and pressures by means of a screw.

The pressure is maintained to achieve the desired dimension and shape.

The part is held and cooled in the mould until it solidifies.

The mould is then opened and the part is released.